pulley lagging,rubber sheet,wear resistant,ceramic rubber sheet,Three-in-one impact resistant ceramic composite liner Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com

**Product Specifications:**

- **Model No.:** TSE-75

- **Motor Power:** 110kW, 132kW, 160kW

- **Diameter:** 71mm

- **L/D Ratio:** 32–64

- **Capacity:** 300–600kg/h

- **Color Options:** Available in any color as per customer requirements

- **Warranty:** 1 Year

- **Trademark:** Haisi

- **Packaging:** Wooden cases or customized packaging

- **Certifications:** CE, ISO9001, TUV, SGS

- **Origin:** Nanjing, Jiangsu

- **HS Code:** 84772090

---

**Representative Materials and Applications:**

- **Mixing Nature-Changing:** PE, PP, PS + SBS, PA + EPDM, PP + NBR, EVA + Silicon rubber; PE, PA, PC, CPE + ABS, ABS + TPU, PBT + PET, PP + PE

- **Filling Nature-Changing:** PE, PP, EVA + Calcium carbonate, talcum powder, titanium powder; PP, PA, ABS + ferrous powder, sulfur powder, ceramic powder

- **Functional Pellets:** PP, PA, ABS, PBT + flame retardants, etc. – Combustion-supporting pellets

- **Biodegradable Pellets:** PE, PP, PS + starch

- **Dual-Prevention Pellets:** PE + fog-preventing agent, stabilizer

- **Black Pellets:** PE, EVA, ABS + carbon black

- **Colored Pellets:** PE, PMMA, ABS, AS, PA, EVA, PET + pigments and additives

- **Reinforced Fibers:** PP, PBT, ABS, AS, PA, PC, POM, PPS, PET + long fibers, carbon fibers, crystals, etc.

---

**Product Images:**

---

**Technical Specifications Table:**

| Model | Diameter | L/D Ratio | Screw Speed | Motor Power | Torque | Capacity |

|-----------|----------|-----------|-------------|-------------|--------|------------------|

| TSE-20B | 22mm | 32–44 | 600r/min | 5.5kW | 43 | 0.5–10 kg/h |

| TSE-30B | 31mm | 32–48 | 600r/min | 15kW | 119 | 5–30 kg/h |

| TSE-40B | 41mm | 32–52 | 600r/min | 30kW | 239 | 90–150 kg/h |

| TSE-52B | 51.5mm | 32–56 | 600r/min | 55kW | 438 | 225–300 kg/h |

| TSE-65B | 62.4mm | 32–60 | 600r/min | 90kW | 716 | 200–300 kg/h |

| TSE-75A | 71mm | 32–64 | 600r/min | 110kW | 1050 | 250–350 kg/h |

| TSE-75B | 71mm | 32–64 | 600r/min | 132kW | 1050 | 300–600 kg/h |

| TSE-75C | 71mm | 32–64 | 600r/min | 160kW | 1990 | 500–1000 kg/h |

| TSE-95B | 93mm | 32–64 | 600r/min | 250kW | 2387 | 800–1200 kg/h |

| TSE-95C | 93mm | 32–64 | 600r/min | 315kW | 2506 | 900–1300 kg/h |

| TSE-120B | 133mm | 32–64 | 600r/min | 550kW | 7162 | 1500–2250 kg/h |

---

The TSE-75 twin screw extruder is a high-performance machine designed for a wide range of plastic processing applications. It supports various material blends and offers flexible customization options, making it suitable for both small-scale and industrial production. With its robust construction and advanced technology, this extruder ensures efficient and consistent performance, meeting international quality standards such as CE, ISO9001, TUV, and SGS. The product is manufactured in Nanjing, Jiangsu, and comes with a one-year warranty to ensure customer satisfaction.

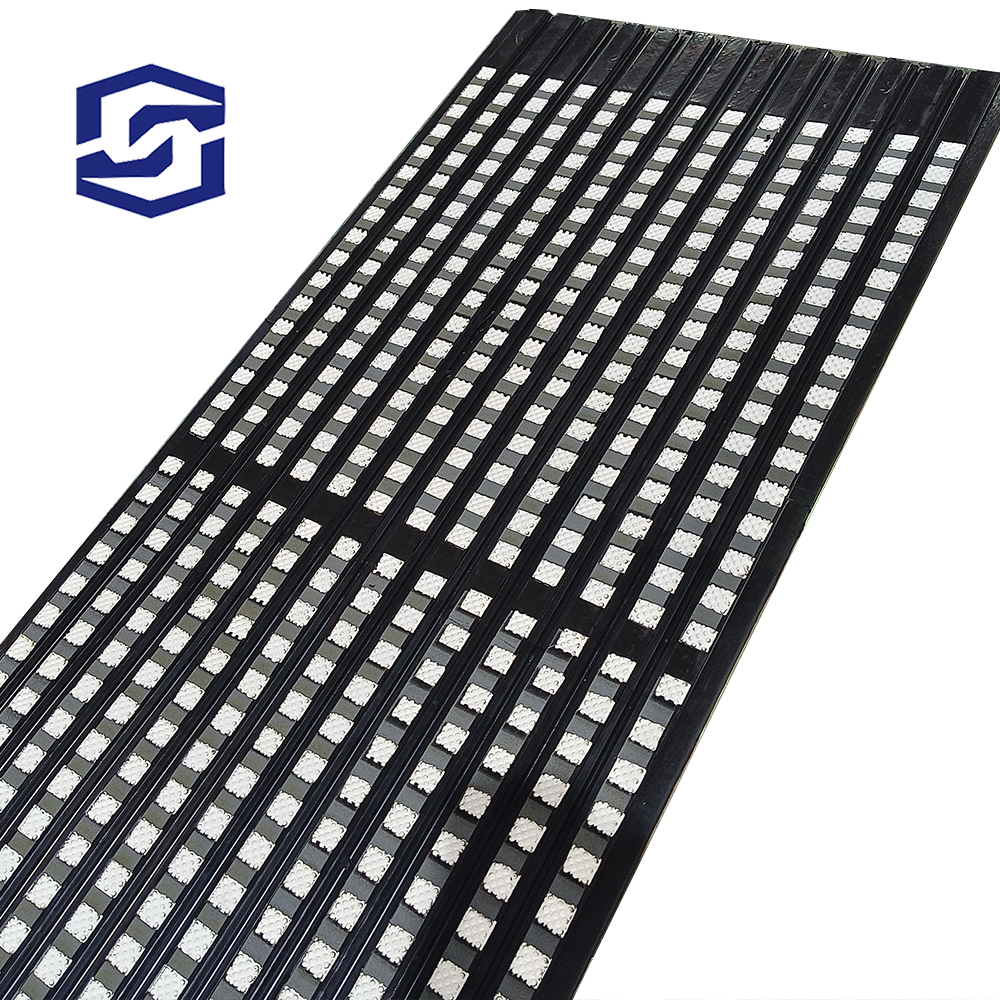

Wear resistant ceramic series, ceramic rubber sheet three-in-one composite liner combines the advantages of ceramic's high hardness and rubber's high cushioning, with wear resistant and impact resistant performance, which can solve the problem of anti-abrasion of the equipment in the process of conveying bulky materials and effectively reduce the environmental noise.

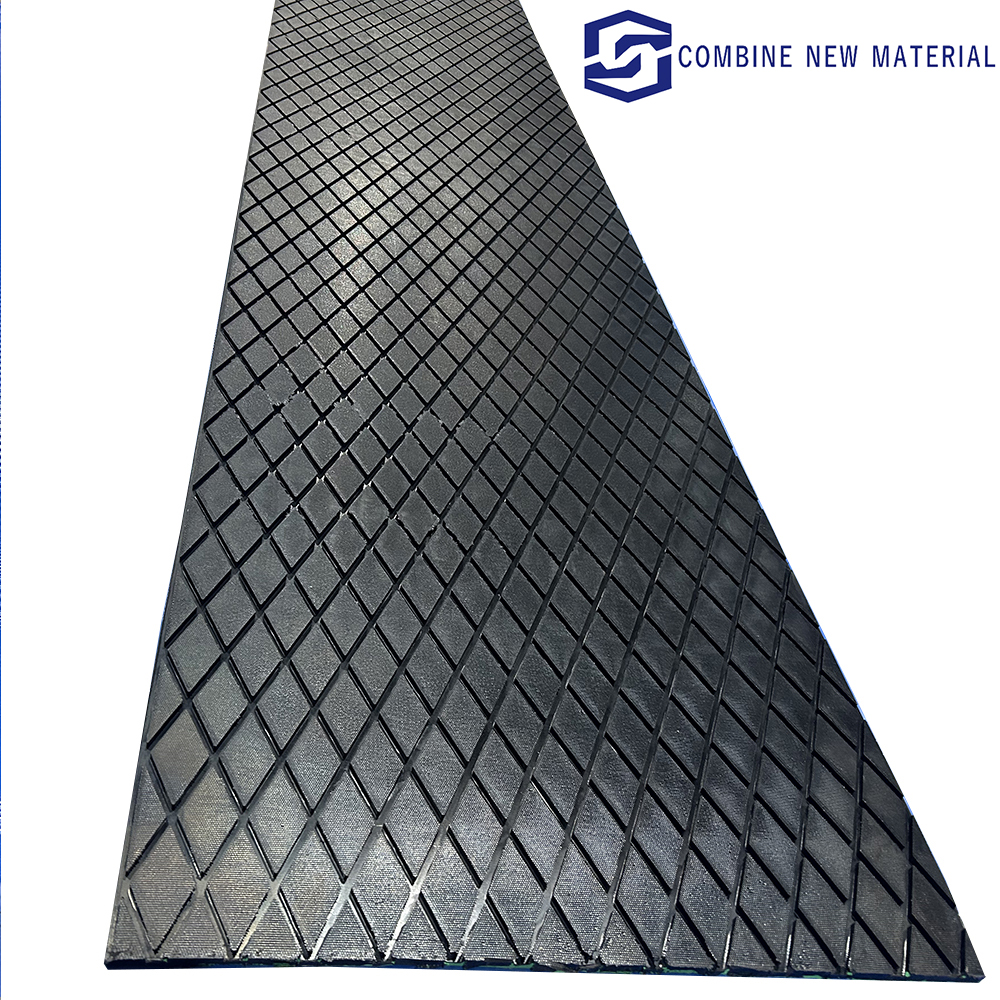

Roller covered is an important part of the belt conveyor transportation system, after covered the roller can effectively improve the operating conditions of the conveyor system, to protect the metal roller from wear and tear, rhombic pattern, ceramic rubber plate coating surface, can increase the friction on the surface of the rubber plate, to prevent the sliding friction between the roller and the belt to reduce the belt slipping, to reduce the roller surface of the material adhesion, so as to reduce the belt deflection and abrasion, so that the roller synchronized with the belt to ensure efficient operation of the belt.