Roller Covered Rhombic Rubber Sheet rhombic rubber sheet,pulley lagging rubber sheet,rubber pulley lagging,Roller covered rhombic rubber sheet,rhombic rubber plate Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com

Here is the rewritten and improved English version of your content, with a more natural and human-like tone, and expanded to over 500 characters:

---

**Model No.:** TSE-75

**Motor Power:** 110kW, 132kW, 160kW

**Diameter:** 71mm

**L/D Ratio:** 32–60

**Capacity:** 300–600kg/H

**Color:** Available in any color as per customer requirements

**Warranty:** 1 Year

**Trademark:** Haisi

**Packaging:** Wooden cases or customized packaging

**Certifications:** CE, ISO9001, TUV, SGS

**Origin:** Nanjing, Jiangsu

**HS Code:** 84772090

The **TSE-75** twin-screw extruder is a high-performance machine designed for efficient compounding and processing of various polymer materials. It is widely used in the production of plastic pellets, masterbatches, and compound materials.

**Representative Materials:**

- **Mixing Nature-Changing:** PE, PP, PS + SBS, PA + EPDM, PP + NBR, EVA + Silicon rubber

- **PE, PA, PC, CPE + ABS, ABS + TPU, PBT + PET, PP + PE**

- **Filling Nature-Changing:** PE, PP, EVA + Calcium carbonate, Talcum powder, Titanium dioxide

- **PP, PA, ABS + Ferrous powder, Sulfuric powder, Ceramic powder**

- **Functional Pellets:** PP, PA, ABS, PBT + Flame retardants, anti-static agents, etc.

- **Biodegradable Pellets:** PE, PP, PS + Starch

- **Anti-fogging & UV-stabilized Pellets:** PE + Anti-fog agent, stabilizer

- **Black Pellets:** PE, EVA, ABS + Carbon black

- **Colored Pellets:** PE, PMMA, ABS, AS, PA, EVA, PET + Pigments and additives

- **Reinforced Fibers:** PP, PBT, ABS, AS, PA, PC, POM, PPS, PET + Long fibers, carbon fibers, crystals

This machine is ideal for producing a wide range of specialized plastic products, including colored, functional, and reinforced pellets. It is equipped with a powerful motor and high torque, ensuring consistent performance and high output capacity.

Below is a detailed specification table for the TSE series of twin-screw extruders:

| Model | Diameter | L/D Ratio | Screw Speed (r/min) | Motor Power | Torque | Capacity (kg/h) |

|-----------|----------|-----------|---------------------|-------------|--------|------------------|

| TSE-20B | 22mm | 32–44 | 600 | 5.5kW | 43 | 0.5–10 |

| TSE-30B | 31mm | 32–48 | 600 | 15kW | 119 | 5–30 |

| TSE-40B | 41mm | 32–52 | 600 | 30kW | 239 | 90–150 |

| TSE-52B | 51.5mm | 32–56 | 600 | 55kW | 438 | 225–300 |

| TSE-65B | 62.4mm | 32–60 | 600 | 90kW | 716 | 200–300 |

| TSE-75A | 71mm | 32–64 | 600 | 110kW | 1050 | 250–350 |

| TSE-75B | 71mm | 32–64 | 600 | 132kW | 1050 | 300–600 |

| TSE-75C | 71mm | 32–64 | 600 | 160kW | 1990 | 500–1000 |

| TSE-95B | 93mm | 32–64 | 600 | 250kW | 2387 | 800–1200 |

| TSE-95C | 93mm | 32–64 | 600 | 315kW | 2506 | 900–1300 |

| TSE-120B | 133mm | 32–64 | 600 | 550kW | 7162 | 1500–2250 |

The **TSE-75** model is particularly suitable for large-scale production due to its high capacity and efficiency. Whether you're looking for standard or custom solutions, this extruder offers flexibility and reliability for a wide range of applications.

---

Let me know if you'd like it formatted for a website or product page.

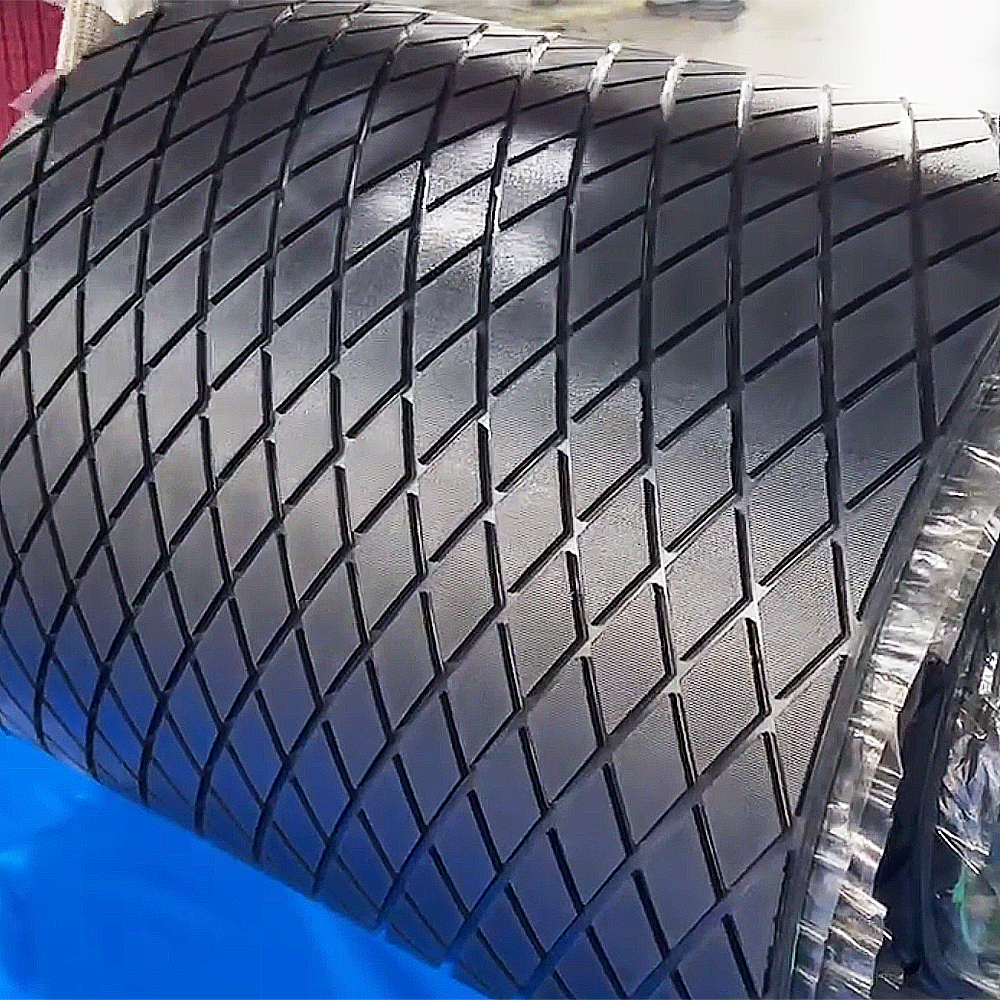

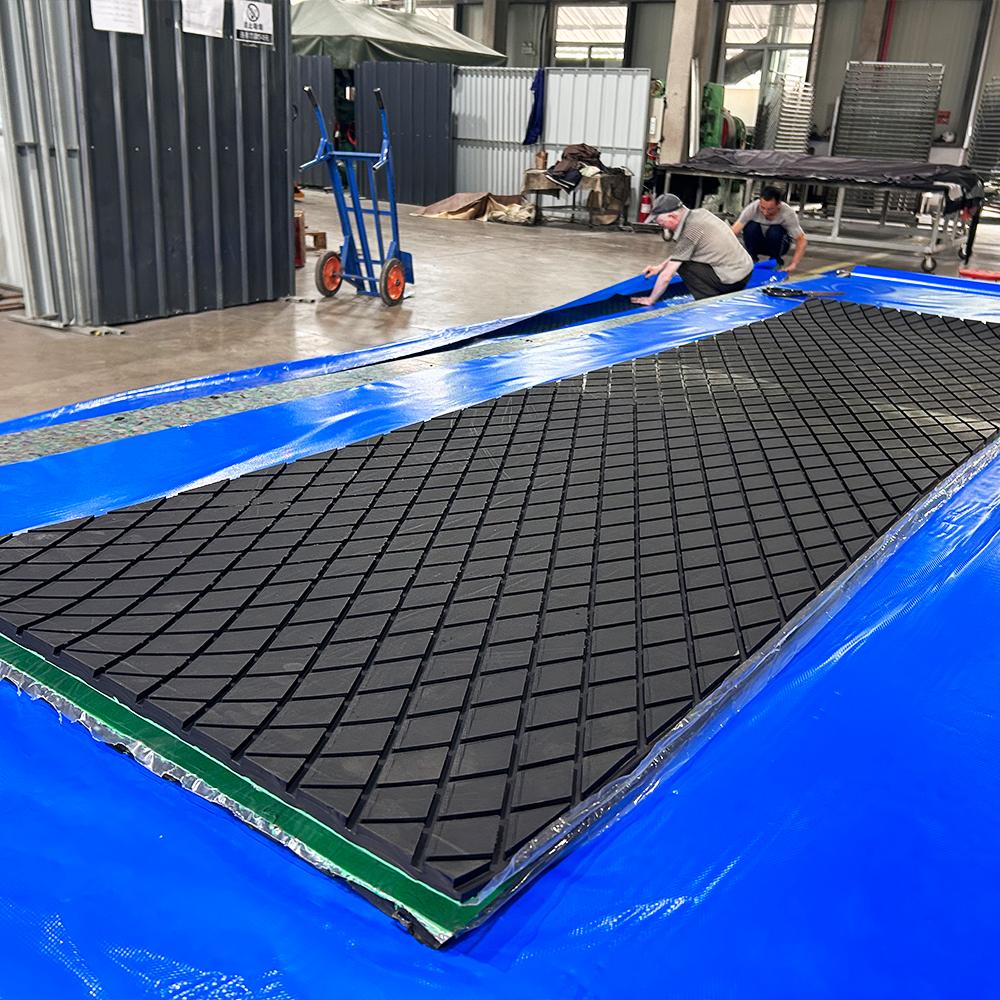

Roller cover rubber free sanding wear resistant rhombic rubber sheet is also known as “rhombic roller cover rubber” is a kind of pre-slotted rubber sheet, suitable for active wheel cover rubber.

The rubber sheet has molded regular rhombic blocks, which protects the surface of the drum from adhering to the transport material and avoids deflection.The regular rhombic blocks can improve the sliding friction coefficient of the rubber sheet, which is also the characteristic of the rhombic rubber sheet, and the high sliding friction coefficient can reduce the slippage between the roller and the conveyor belt.

Still struggling with frequent roller changes and production interruptions? Choosing our roller covers with rhombic rubber sheets will completely change your operation! The unique rhombic pattern with carefully designed grooves provides superior grip and ensures smooth material transfer in even the harshest environments. Whether it's an abrasive mine, a busy harbour or a hectic factory, our rhombic rubber sheeting resists wear, tear and corrosion in any environment. Say goodbye to downtime and hello to soaring productivity.