Exhaust Manifold,3968362 Exhaust Manifold Of Cummins 4B 6B 6C,Exhaust Manifold 3968362 For Cummins 8.3L,Cummins Engine Part 3968362 Exhaust Manifold ACRO (TIANJIN) INTERNATIONAL TRADE CO., LTD , https://www.acrospareparts.com

# Working in Enclosed Areas: A Comprehensive Guide to Confined Space Operations

A confined space is essentially a defined area within a structure or system where work is carried out. However, not every enclosed space qualifies as a confined space. For instance, the interior of an airplane hangar wouldn't be classified as such because it doesn't meet the necessary criteria.

To qualify as a confined space, three key conditions must be present:

1. The space must be sufficiently large to allow a person to enter and work within it.

2. It must have restricted access or exit points.

3. It should not be designed for regular human occupancy.

For example, when an inspector enters a massive boiler or storage tank for examination, they're performing work in a confined space. Conversely, an airplane hangar wouldn't be considered a confined space since there aren't limited entry or exit points.

These types of spaces can be found both above and below ground level and are quite common in various industrial settings. Other terms for confined spaces include enclosed area, confined environment, or simply confined room.

Despite their enclosed nature, confined spaces can vary greatly in size. Take, for instance, a scrubber, officially known as a flue gas desulfurization (FGD) unit, used to clean SO2 emissions from coal-fired power plant exhausts. These scrubbers can reach heights of up to 80 feet. Similarly, industrial boilers and storage tanks, which also require periodic internal inspections, present vast, cavernous environments that still count as confined spaces due to meeting the aforementioned criteria.

This guide will delve into how people perform work in these confined areas, the potential dangers involved, the tools used for such work, and the regulatory and permitting aspects of confined space operations.

## Identifying a Confined Space

Most confined spaces are easily identifiable due to their indoor location and the fulfillment of the three criteria: sufficient size for entry, lack of continuous human occupancy, and limited entry/exit points.

However, some cases require a bit more imagination. For example, a trench could be considered a confined space if accessing or leaving it proves challenging. Another intriguing example is the inside of an airplane's wing, which requires regular inspection and thus involves confined space work.

Another factor aiding identification is considering the safety implications of working in the space. A confined space often presents fatal conditions, such as toxic gases or harmful materials, though these aren't strictly necessary to classify it as such.

Consider a grain bin, where falling into the grain can quickly lead to drowning. Large sewer pipes, containing hazardous biological or chemical substances, present another example.

### Industries Involving Confined Space Work

The following industries frequently involve work in confined spaces:

#### Oil & Gas

- Chimneys and smokestacks

- Offshore rigs

- Floating Production Storage and Offloading units (FPSOs)

- Drilling ships

- Jetties

- Storage tanks

- Refineries

#### Chemical Industry

- Fermenter tanks

- Pressure vessels and storage tanks

- Fiberglass storage tanks

- Heat exchangers

- Storage silos and bins

#### Mining

- Stopes

- Ore passes

- Crushers

- Other areas as needed, including equipment supporting mining operations

#### Power Generation

- Coal-fired boilers

- Recovery boilers

- Heat recovery steam generators

- Wind turbines

- Nuclear power plants

- Hydroelectric power plants

- Chimneys and stacks

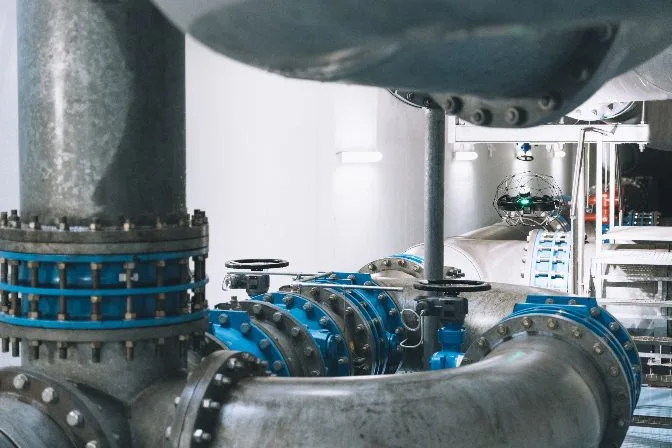

#### Wastewater Infrastructure

- Pipes

- Water outfalls

- Storm drains

- Manholes

- Culverts

- Ditches, wells, and trenches when access or egress is limited but still have "blue sky" above

#### Maritime (including shipping yards and marine vessels)

- Ballast tanks

- Barges

- Shipping containers

- Fish holds

#### Construction (residential and commercial properties)

- Crawl spaces

- Vaults

- Sub-cellars

- Cold storage

- Tunnels

Additional examples of confined spaces include bins, silos, vats, hoppers, water supply towers, aircraft wings, and manure pits.

## Types of Work Commonly Done in Confined Spaces

Two primary types of work are typically conducted in confined spaces:

1. **Inspections**

2. **Repairs**

Inspections and repairs form integral parts of the maintenance process. Inspectors detect potential defects within assets, which guides maintenance decisions, such as whether to repair, replace, or monitor the asset for further observation.

For instance, ballast tanks, used to stabilize ships by pumping seawater in and out, often suffer from corrosion due to seawater salinity. Inspectors periodically empty these tanks and enter them to check for signs of wear. While spotting corrosion doesn't necessarily prompt immediate repairs, it may lead to a monitoring plan to ensure the tank's integrity isn't compromised.

Such inspections are vital for extending the lifespan of industrial assets. In industries handling explosive materials, like Oil & Gas, inspections are also critical for safety, preventing accidents due to poorly maintained equipment.

Inspectors have a variety of inspection techniques at their disposal, collectively referred to as Non-Destructive Testing (NDT), as they offer different ways to inspect materials without damaging them.

Common NDT methods used in confined spaces include:

- Visual NDT (VT)

- Acoustic Emission NDT (AE)

- Eddy Current NDT (ET)

- Leak Testing NDT (LT)

- Dye Penetrant NDT (PT)

- Magnetic Particle NDT (MT)

- Radiography NDT (RT)

- Ultrasonic NDT (UT)

## Dangers of Confined Space Work

Working in confined spaces poses significant risks. According to the U.S. Bureau of Labor Statistics, from 2011 to 2018, 1,030 individuals in the U.S. alone lost their lives due to occupational injuries involving confined spaces.

Factors contributing to these dangers include:

- **Atmosphere**: Oxygen deficiency/enrichment, presence of asphyxiants, or traces of noxious gases/chemicals.

- **Chemical and Biological Exposures**: Contact with hazardous chemicals or bacteria via skin, ingestion, or inhalation.

- **Fire Hazards**: Explosive or flammable atmospheres due to flammable liquids/gases and combustible dust.

- **Potential for Engulfment**: Risks of being surrounded and captured by a liquid or flowable solid, such as grain.

- **Mechanical and Physical Hazards**: Noise, extreme temperatures, radiation, vibration, electrical hazards, structural issues, falling debris, collapse, moving equipment parts, inadequate lighting, entanglement, engulfment, slips, and falls.

Other risks associated with confined space work:

- **Rescues**: According to Canada's Centre for Occupational Health and Safety, 60% of fatalities in confined spaces result from attempted rescues.

- **Work at Height**: Inspectors and maintenance crews often work on scaffolding or using ropes, adding another layer of potential danger.

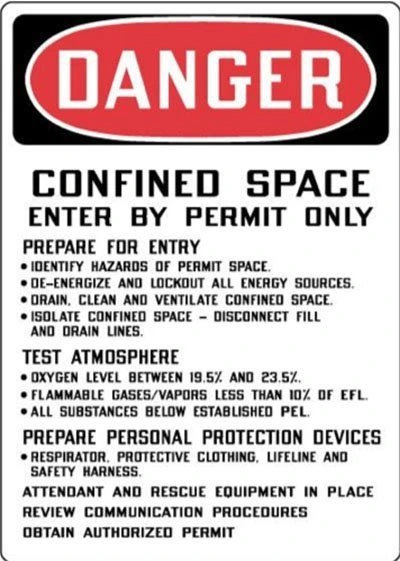

### Procedure for Entering a Confined Space: Planning to Mitigate Risk

After receiving necessary training and permits, the following steps are typically recommended for planning safe confined space operations:

**1. Initial Survey of the Space and Work**

During the survey, workers should:

- Identify potential hazards for work in the space.

- Complete a risk assessment documenting the likelihood, magnitude, and potential consequences of each hazard.

- Document the number of employees working in the space.

- Note any potential changes or activities that could occur in the space.

**2. Create and Implement a Plan**

After the survey, workers should prepare the area for work by:

- Posting signage and setting up barricades—clear signage indicating confined space work is underway and barricading entry/exit points.

- Planning for rescues and emergencies—developing a clear plan addressing each hazard identified in the survey.

- Clarifying the role of the standby person—identifying a standby person and detailing the specific steps they will take in case of a rescue/emergency.

**3. Mitigate Any Hazards Found**

Steps must be taken to mitigate identified hazards before entering the space:

- Isolate hazards.

- Clean, purge, and ventilate the space.

- Test and monitor the atmosphere.

For regular confined space entry operations, a confined space hazard assessment and control program should be established, outlining protocols for all the above steps.

## Confined Space Equipment

Even on newly commissioned assets, much effort is put into designing to minimize the need for entry into confined spaces, though complete avoidance is often unfeasible.

### Personal Protective Equipment (PPE) for Work in Confined Spaces

The type of PPE required depends partly on the specific confined space where work is planned.

Examples of commonly used PPE in confined spaces include:

- Hard hats

- Gloves

- Eye and face protection

- Foot protection

- Flame-resistant clothing (for potentially explosive environments)

- Chemical gloves (for working with chemicals)

- Fall protection harnesses (for working at height)

### Equipment for Human Entry in Confined Spaces

In addition to PPE, certain equipment is often used to assist workers in accessing and working inside confined spaces.

#### Systems for Confined Space Entry

These systems aid workers in horizontally or vertically entering areas that are hard to access, such as pressure vessels or manholes.

#### Hoists

Hoists are used for lifting, lowering, and positioning personnel and materials within confined space applications.

#### Retractable Devices

These devices provide workers in confined spaces with fall protection, offering bi-directional retrieval.

### Equipment to Support Remote Data Collection in Confined Space Work

Increasingly, inspectors are reducing the need for human confined space entry by deploying robots to handle specific tasks in these hazardous areas.

Most robotics solutions used in these spaces are designed for collecting visual data for inspections. However, some robots can not only collect data but also perform repairs. For example, in sewer systems, new robotic tools can repair leaks in pipes.

All of the robotics equipment listed below is currently used solely for inspections, meaning remote data collection, but as technology advances, we'll likely see more tools capable of finding and fixing defects.

#### Camera-on-a-Stick

A DIY or industrialized "camera-on-a-stick" is essentially a camera lowered into a confined space from the top. Though simple in design, this method offers a cost-effective and efficient way to collect images without human entry.

Searchcam's Camera-on-a-stick

Note that these devices are limited in their access—they can only capture imagery visible from the insertion point(s).

#### Crawler Robots

Crawler robots are ideal for inspecting long spaces with consistent geometry, such as pipes and ducts.

Pipe inspection crawler from Inuktun

These robots are usually tethered to an external power source and data link. This enables inspectors to perform live inspections over hundreds of meters down a pipe for extended periods. However, crawlers work best in situations without significant obstacles, T-junctions, or major changes in pipe diameter.

#### Snake Robots

Snake robots can enter through a manhole and be operated inside a tank. Inspectors can maneuver them around internal components to access nearly any location close enough to the entry point.

Snake robot from the Petrobot research project

The main drawbacks of such systems are their significant weight and large footprint.

#### Climber Robots

Climber robots use magnets to navigate vertical surfaces, allowing them to move freely across the surfaces of metallic confined spaces, provided the environment lacks sharp angles that could obstruct movement.

The HR-MP20 Light Weight Magnetic Climbing Robot from Helical Robotics

While some miniature versions exist, most climber robots are typically heavy and expensive equipment.

### Confined Space Inspection Drones

Drones are another type of equipment increasingly used for inspection work in confined spaces.

However, not just any drone can operate in confined areas. Due to the unique limitations of these spaces, specialized confined space inspection drones, like Flyability's Elios 3, are typically required.

The Elios 3, Flyability's confined space inspection drone

Unlike ground-based robots, indoor drones offer a significant advantage in versatility. Their three-dimensional mobility allows access to virtually any location, from any angle, regardless of the environment's shape, material, or geometry.

Yet, multiple challenges await drones when flying indoors. These include turbulence due to small air volumes or drafts, the presence of dust, signal transmission issues, complete darkness, and reflective surfaces that can degrade image quality.

Additionally, the confined space itself increases the likelihood of collisions.

The Elios 3 was designed to tackle all these challenges. Specifically, it was engineered for inspections in confined spaces.

The Elios 3 is encased in a protective cage and features collision-tolerance capabilities, enabling inspectors to fly it in tight confined spaces to collect visual data without fear of crashing. If the drone bumps into a wall or other surface, it can continue flying undamaged.

It also boasts unique lighting and stability features, allowing it to capture high-quality images even in dusty or pitch-black environments.

The Elios 3 flying inside a mine

[Case Study: Elios 3's 3D Mapping Assists City of Lausanne with Water Department Inspections.]

## Confined Space Training and Permit Requirements

Given the dangers associated with confined spaces, most countries have stringent standards, including training and permit requirements, for working in them.

Some standards are general and industry-agnostic, while others are industry-specific.

Standards guide proper design, safeguarding, and maintenance of equipment where confined spaces are involved. During plant design, the goal is to eliminate the need for confined space work altogether, though this isn't always feasible.

### Confined Space Training

Due to the dangers and complexities of confined space entry, special training is usually required for certification in this field.

This training typically helps workers maximize safety by identifying hazards and establishing strong planning protocols.

A typical list of skills covered in confined space training includes learning how to:

- Test the air quality for safety in the space

- Lock and tag out connecting piping

- Force ventilation

- Observe workers in the space to make safety decisions

- Develop a rescue plan ahead of entry

In the U.S., OSHA requires anyone planning to enter or work around a confined space to be certified under the OSHA Confined Spaces standard 29 CFR 1910.146.

To achieve this certification, OSHA requires workers to score 80% or higher on a written exam demonstrating they can:

- Determine what constitutes a "confined space" and whether it's a Permit-Required Confined Space (PRCS)

- Understand the application and scope of OSHA's confined space entry standards

- Understand OSHA's requirements for safely developing and running a PRCS entry program

- Identify when to use OSHA's alternate entry and reclassification procedures

- Know the responsibilities of entrants, attendants, entry supervisors, and contractors

- Understand the requirements for emergency services and rescue

- Have basic knowledge of general use and limitation of related equipment

### Confined Space Permits

Most confined spaces require workers to obtain some form of permit before working in them (exceptions are outlined in the next section).

In the U.S., determining whether a permit is needed hinges on whether the work will be performed in a Permit-Required Confined Space (PRCS).

OSHA defines a PRCS as one that:

- Contains or has the potential to contain a hazardous atmosphere.

- Contains a material that has the potential to engulf an entrant.

- Has an internal configuration that could trap or asphyxiate an entrant, such as inwardly converging walls or a floor that slopes downward and tapers to a smaller cross-section.

- Or contains any other recognized serious safety or health hazard.

Once a permit is obtained, workers must assess hazards present in the space, develop an entry plan, and create a rescue plan.

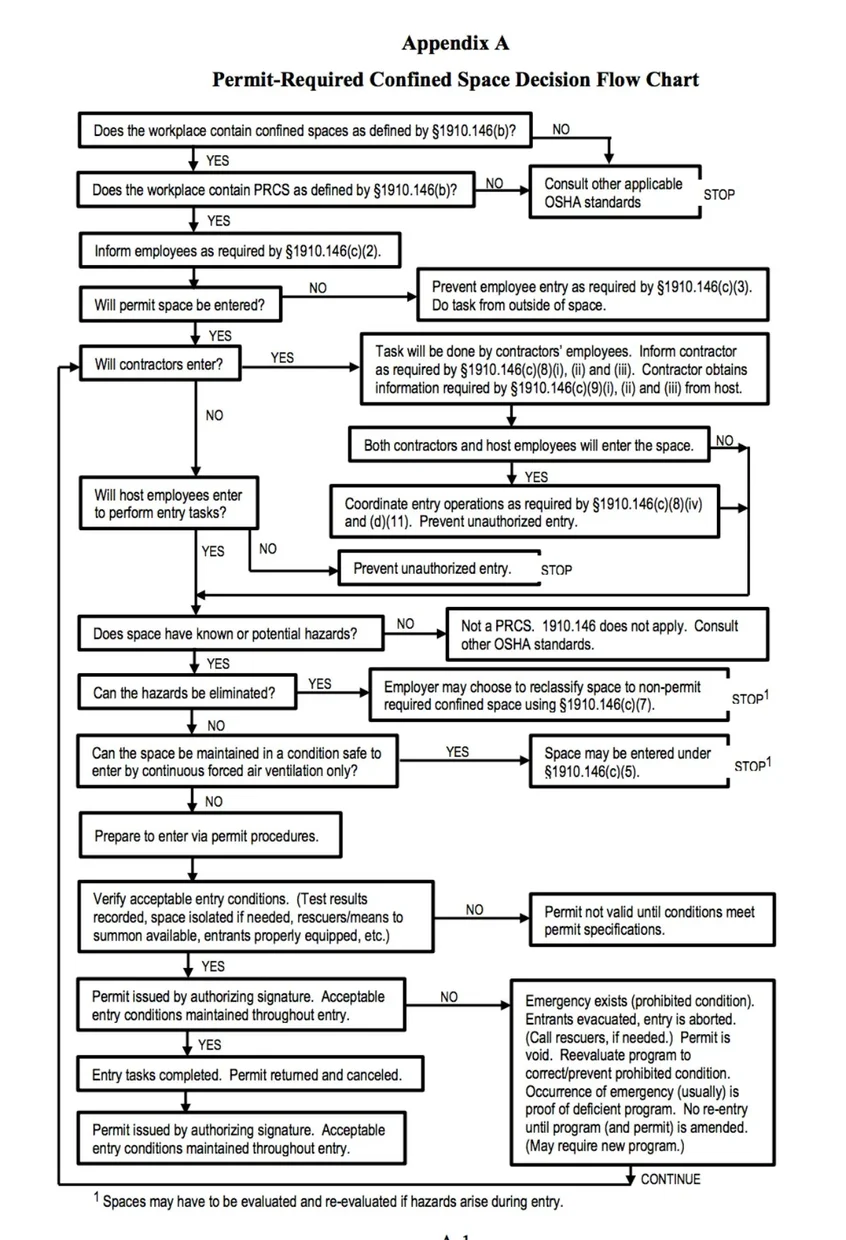

For a comprehensive view of confined space entry procedures, refer to OSHA's PRCS Decision Flow Chart:

### Non-Permit-Required Confined Spaces

Certain confined spaces meet the definition of a confined space but don't require permits for work to be done.

Examples include:

- Equipment closets

- Crawl spaces under houses

- Machinery cabinets

- Ventilated tunnels

- Drop ceilings

### Confined Space Work Standards and Codes

**OSHA**

- Confined Spaces

- Appendix A: Permit-required Confined Space Decision Flow Chart

- Appendix B: Procedures for Atmospheric Testing

- Appendix C: Examples of Permit-required Confined Space Programs

- Appendix D: Confined Space Pre-Entry Checklist

- Appendix E: Sewer System Entry

- Appendix F (Non-Mandatory): Rescue Team or Rescue Service Evaluation Criteria

**NIOSH** (National Institute for Occupational Safety and Health)

- NIOSH information on Confined Spaces

- NIOSH Preventing Entrapment and Suffocation Caused by the Unstable Surfaces of Stored Grain and Other Materials

- NIOSH Preventing Occupational Fatalities in Confined Spaces

- NIOSH Guide to Safety in Confined Space

**ASSP** (American Society of Safety Professionals)

- ASSP Confined Spaces Standard ANSI/ASSP Z117.1

---

This guide aims to provide a comprehensive overview of confined space work, covering the essential aspects of safety, tools, and regulations.