Cummins turbocharger,turbocharger for Cummins engine, Turbocharger 4035253 fits CUMMINS, Turbo for Cummins ACRO (TIANJIN) INTERNATIONAL TRADE CO., LTD , https://www.acrospareparts.com

# Working in Enclosed Spaces: A Comprehensive Guide

## What Defines a Confined Space?

A confined space is essentially a structure or system where work is conducted, but it’s not designed for continuous human occupancy. Not every internal space qualifies as a confined space. For instance, the vast interior of an airplane hangar wouldn't fall under this category because it offers unrestricted access and exit.

To qualify as a confined space, all of the following criteria must be met:

1. **Sufficient Size**: The space must be large enough for a person to enter and work within.

2. **Limited Access**: It should have restricted ways to enter or exit.

3. **Not Designed for Continuous Occupancy**: It's not built for regular human presence.

Take, for example, an inspector entering a massive boiler or storage tank to carry out checks. This counts as work in a confined space. However, the previously mentioned hangar wouldn't classify as such due to the lack of restricted entry and exit points.

Such spaces can be found both underground and above ground and are quite common across various industries. Other terms for confined spaces include confined area, confined environment, enclosed space, or simply confined room.

## Identifying a Confined Space

Most confined spaces are easily identifiable as they are indoors and fulfill the three criteria mentioned earlier. However, some cases require a bit more imagination to categorize.

For instance, a deep ditch could be considered a confined space if it poses difficulty in entering or exiting. Similarly, the interior of an airplane wing, which needs routine inspection, can also be classified as a confined space.

Another aspect to consider when identifying a confined space is the safety implications of the work conducted within. Often, confined spaces harbor fatal conditions such as toxic gases or hazardous materials. However, the presence of such elements isn’t a prerequisite for labeling a space as confined.

Take, for example, grain bins. These spaces can be extremely dangerous due to the risk of drowning if someone falls into the grain. Similarly, large sewer pipes may contain harmful biological or chemical substances.

## Industries Utilizing Confined Spaces

Confined space work is prevalent across many industries. Here are some of the primary sectors where such work is regularly performed:

### Oil & Gas

- **Chimneys and smokestacks**

- **Offshore rigs**

- **FPSOs (Floating Production Storage and Offloading units)**

- **Drilling ships**

- **Jetties**

- **Storage tanks**

- **Refineries**

### Chemical Industry

- **Fermenter tanks**

- **Pressure vessels and storage tanks**

- **Fiberglass storage tanks**

- **Heat exchangers**

- **Storage silos and bins**

### Mining

- **Stopes**

- **Ore passes**

- **Crushers**

- **Other areas as needed, including in equipment used to support mining operations**

### Power Generation

- **Coal fired boilers**

- **Recovery boilers**

- **Heat recovery steam generators**

- **Wind turbines**

- **Nuclear power plants**

- **Hydro power plants**

- **Chimneys and stacks**

### Wastewater Infrastructure

- **Pipes**

- **Water outfalls**

- **Storm drains**

- **Manholes**

- **Culverts**

- **Ditches, wells, and trenches when access or egress is limited**

### Maritime (including shipping yards and marine vessels)

- **Ballast tanks**

- **Barges**

- **Shipping containers**

- **Fish holds**

### Construction (both residential and commercial properties)

- **Crawl spaces**

- **Vaults**

- **Sub Cellars**

- **Cold storage**

- **Tunnels**

Other examples of confined spaces include:

- **Bins**

- **Silos**

- **Vats**

- **Hoppers**

- **Water supply towers**

- **Aircraft wings**

- **Manure pits**

## Types of Work in Confined Spaces

Two primary types of work are typically carried out in confined spaces:

1. **Inspections**

2. **Repairs**

Inspections and repairs form the backbone of the maintenance process. Inspectors detect potential defects in assets, which helps in making informed maintenance decisions—whether to repair, replace, or monitor the asset temporarily.

For instance, ballast tanks on ships are used to manage the vessel's balance by pumping seawater in and out. Due to seawater’s corrosive nature, these tanks often experience wear and tear. Inspectors conduct periodic inspections by emptying the tanks, then entering them to check for signs of corrosion.

Even if corrosion is detected, immediate repairs aren’t always necessary. Sometimes, the maintenance process simply involves monitoring the defect to ensure it doesn’t worsen or compromise the tank’s integrity.

Inspections are vital for maintaining the lifespan of industrial assets, especially in industries dealing with explosive materials like Oil & Gas, where they also play a critical role in safety by preventing accidents caused by poorly maintained equipment.

When working in confined spaces, inspectors utilize various inspection techniques collectively known as Non-Destructive Testing (NDT), which allows them to examine materials without causing damage.

Common NDT methods used in confined spaces include:

- **Visual Testing (VT)**

- **Acoustic Emission Testing (AE)**

- **Eddy Current Testing (ET)**

- **Leak Testing (LT)**

- **Dye Penetrant Testing (PT)**

- **Magnetic Particle Testing (MT)**

- **Radiography Testing (RT)**

- **Ultrasonic Testing (UT)**

## Hazards of Working in Confined Spaces

Working in confined spaces presents numerous risks. According to the U.S. Bureau of Labor Statistics, from 2011 to 2018, 1,030 people in the U.S. alone lost their lives due to occupational injuries involving confined spaces.

Factors contributing to these dangers include:

- **Atmospheric Hazards**: Spaces may lack sufficient oxygen or contain toxic gases.

- **Chemical and Biological Exposures**: Dangerous substances that can harm through skin contact, ingestion, or inhalation.

- **Fire Hazards**: Flammable atmospheres due to liquids, gases, or combustible dust.

- **Engulfment Risks**: Workers can be trapped by flowing substances like grain.

- **Mechanical and Physical Hazards**: Noise, extreme temperatures, radiation, vibrations, electrical hazards, structural risks, falling debris, collapsing structures, moving machinery parts, poor lighting, entrapments, slips, and falls.

Other dangers include:

- **Rescue Risks**: According to Canada’s Centre for Occupational Health and Safety, 60% of fatalities in confined spaces involve would-be rescuers.

- **Work at Height**: Inspectors often need to work on scaffolds or use ropes, adding another layer of risk.

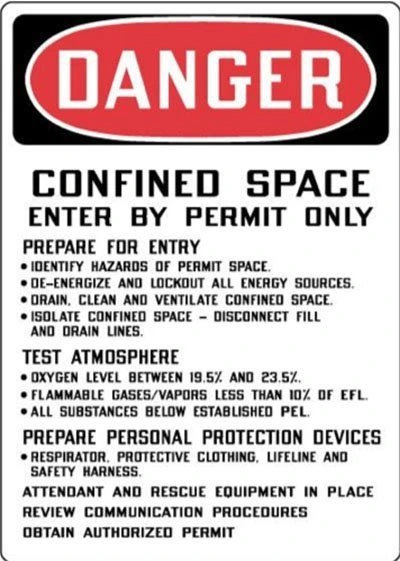

## Planning Confined Space Entry

After receiving proper training and permits, the following steps are typically recommended for safe confined space entry:

1. **Initial Survey**:

- Identify potential hazards.

- Document the likelihood, magnitude, and consequences of each hazard.

- Note the number of employees involved.

- Record possible changes or activities in the space.

2. **Create and Implement a Plan**:

- Set up signage and barriers to indicate confined space work.

- Develop a clear rescue and emergency plan.

- Assign a standby person and outline their role in case of emergencies.

3. **Mitigate Hazards**:

- Isolate potential hazards.

- Clean, purge, and ventilate the space.

- Test and monitor the atmosphere.

For regular confined space entry, a comprehensive hazard assessment and control program should be established, detailing all necessary steps.

## Equipment for Confined Space Work

Despite recent efforts to minimize human entry into confined spaces, complete avoidance is often impractical. Essential equipment includes:

### Personal Protective Equipment (PPE)

The type of PPE depends on the specific confined space. Common items include:

- Hard hats

- Gloves

- Eye and face protection

- Foot protection

- Flame-resistant clothing (for explosive environments)

- Chemical-resistant gloves (for chemical handling)

- Fall protection harnesses (for working at heights)

### Access Systems

Specialized systems assist in horizontal or vertical entry into challenging areas like pressure vessels or manholes.

### Hoists

Used for lifting, lowering, and positioning personnel and materials within confined spaces.

### Retractable Devices

Provide fall protection and enable bi-directional retrieval.

### Remote Data Collection Equipment

Robots are increasingly replacing humans for inspection tasks in confined spaces. Most are designed for visual data collection, though some can perform repairs.

- **Camera-on-a-Stick**: A simple yet effective tool for visual inspections.

- **Crawler Robots**: Ideal for long, consistent geometries like pipes and ducts.

- **Snake Robots**: Versatile for navigating complex confined spaces.

- **Climber Robots**: Use magnets to move on metal surfaces.

## Confined Space Inspection Drones

Drones are another valuable tool for confined space inspections. However, not just any drone suffices. Specialized drones like Flyability’s Elios 3 are designed for confined spaces.

Unlike ground-based robots, indoor drones offer unmatched versatility. Their three-dimensional mobility allows access to virtually any location, from any angle, regardless of the environment's shape or material.

However, indoor drones face unique challenges: turbulence, dust, signal interference, darkness, and reflective surfaces. The Elios 3 was engineered to overcome these issues. It features a protective cage and collision tolerance, enabling inspectors to safely gather visual data in tight spaces.

It also boasts advanced lighting and stabilization features, ensuring high-quality imagery even in challenging conditions.

## Confined Space Training and Permits

Due to the inherent dangers of confined spaces, most countries enforce strict standards, including training and permit requirements, for working in them.

Training programs focus on identifying hazards and creating robust safety plans. In the U.S., OSHA mandates certification under the Confined Spaces standard 29 CFR 1910.146. Certification requires passing an 80% or higher on a written exam covering key concepts.

Permits are usually required for confined space work unless the space is deemed non-permit-required. Examples of non-permit-required spaces include equipment closets, crawl spaces, ventilated tunnels, and drop ceilings.

## Conclusion

Working in confined spaces is fraught with challenges and risks, but with proper planning, training, and equipment, the dangers can be mitigated. Understanding the nature of confined spaces, identifying potential hazards, and utilizing appropriate tools and techniques are essential for ensuring worker safety and efficient maintenance operations.