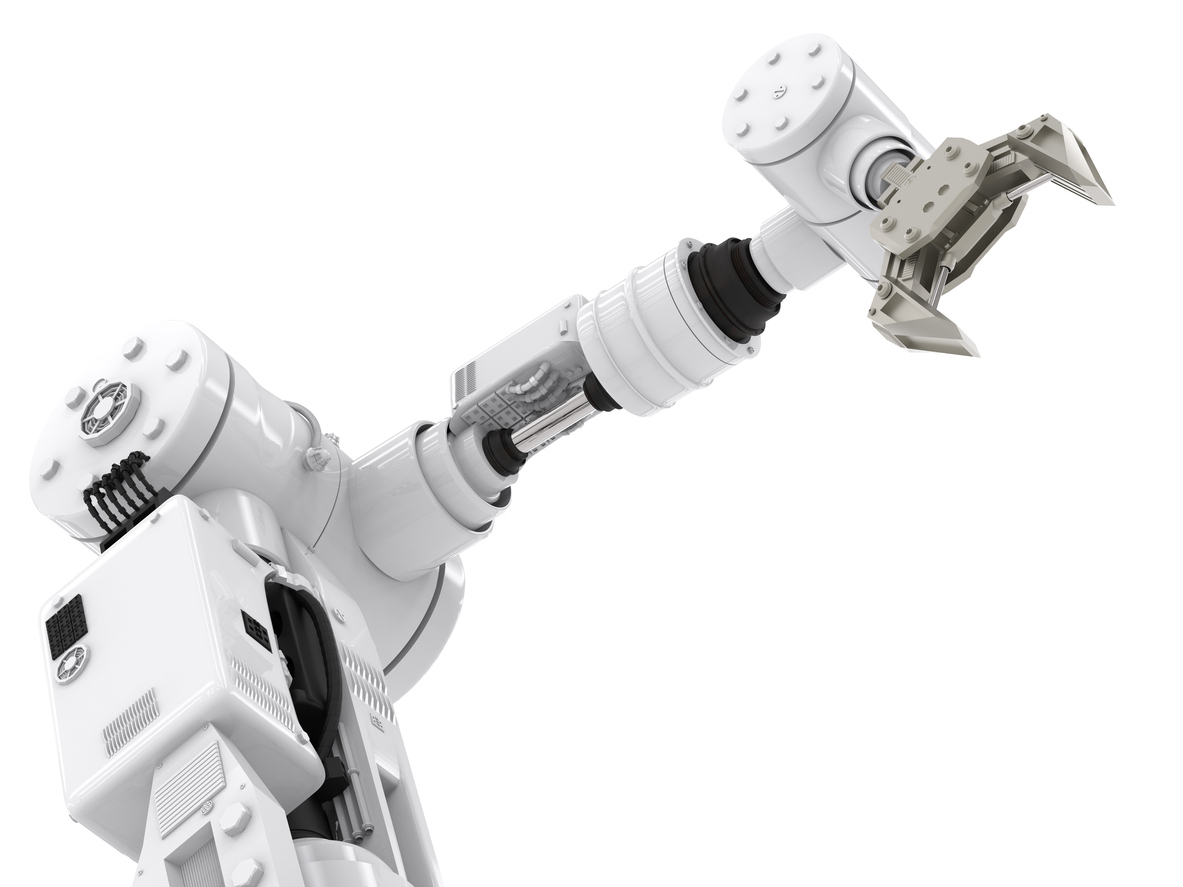

When it comes to machine tending applications, industrial robots have become indispensable tools for improving productivity and reducing cycle times. These robotic solutions offer numerous advantages over traditional manual methods, allowing manufacturers to achieve significant efficiency gains. By automating repetitive tasks, companies can minimize human error, reduce labor costs, and maximize throughput. One of the most compelling reasons to invest in robotic machine tending is the potential for substantial return on investment (ROI). When implemented correctly, robotic systems can pay for themselves within a relatively short period while delivering consistent performance improvements. However, achieving this level of success requires careful consideration of several key factors. For an industrial robot to excel in machine tending roles, it must possess specific characteristics that ensure optimal performance and reliability. Among these critical attributes are: By integrating these elements into their designs, businesses can create robust robotic systems capable of meeting demanding requirements while providing long-term economic benefits. Agricultural machinery producers frequently face challenges related to maintaining high output rates amidst changing product lines. Recently, Genesis Systems Group worked alongside one such client—an agricultural component manufacturer seeking ways to streamline its machining processes through automation. With sixteen distinct part configurations needing attention daily, implementing fully autonomous solutions seemed like an ideal approach toward enhancing competitiveness. Their chosen configuration consisted of a single robotic workstation equipped with dual three-finger grippers mounted on a rotating platform capable of turning 180 degrees between operations. Additionally, integration of a two-dimensional vision system assisted with precise positioning while illuminating areas using red LED lights enhanced contrast during inspections. These features combined enabled the unit to manage tasks efficiently with minimal supervision, resulting in overall cycle times dropping below sixty seconds per piece while sustaining near-perfect operational availability at ninety-five percent uptime figures. This initiative proved successful beyond expectations; not only did it eliminate bottlenecks present previously but also delivered impressive financial returns almost immediately after deployment. For those interested further details regarding this particular project can be found within Genesis' official documentation available online. As industries continue evolving rapidly towards greater digitalization, embracing advanced technologies like robotics presents countless opportunities for growth. Manufacturers who embrace change early stand poised to reap rewards far exceeding initial investments made today! A Wood Fired Pizza Oven is a timeless piece of culinary equipment, revered for its ability to produce pizzas with unparalleled flavor and texture. Constructed from robust materials like brick, clay, or stone, these ovens are designed to withstand intense heat while providing even cooking surfaces. The heart of a wood fired oven is its domed interior, which allows for optimal heat retention and circulation, ensuring that each pizza is cooked to perfection. The unique appeal of a wood fired pizza oven lies in its ability to impart a distinct, smoky flavor to the pizza, something that cannot be replicated by gas or electric ovens. The high temperatures, often reaching up to 900 degrees Fahrenheit (482 degrees Celsius), create a crispy, blistered crust while keeping the toppings perfectly melted and caramelized. The process of building and maintaining the fire adds an element of artistry and tradition, connecting the cook to centuries of pizza-making heritage. Using a wood fired oven involves skill and patience. The fire must be carefully built and maintained to achieve the desired temperature. The pizza, typically cooked directly on the oven's hot surface, requires careful monitoring and occasional rotation to ensure an even bake. This hands-on approach not only enhances the cooking experience but also results in pizzas with a rustic, artisanal quality. Wood fired pizza ovens are more than just functional cooking tools; they are also beautiful additions to any kitchen or outdoor space. Their classic design and warm, glowing interior create a focal point for gatherings, drawing friends and family together around the promise of delicious, homemade pizza. The process of making pizza in a wood fired oven becomes a communal activity, filled with anticipation and enjoyment. Wood Fired Pizza Oven bbq,outdoor Wood Fired Pizza Oven,Pizza oven bbq outdoor,portable Wood Fired Pizza Oven,folding Wood Fired Pizza Oven gftop , https://www.gftopgrill.comEnhancing Efficiency in Machine Tending with Industrial Robotics

The Critical Components of a Successful Robotic Machine Tending System

Case Study: Transforming Agricultural Component Production Through Automation

# Reducing Cycle Times in Machine Tending with Industrial Robots

Category: Robotic Machine Tending