In machine tending operations, industrial robots offer a significant advantage by dramatically reducing cycle times, thereby enhancing overall productivity. Compared to manual machine tending, robotic systems bring numerous advantages that contribute to shorter cycle times.

The implementation of robotic machine tending can significantly impact a manufacturer's profitability, providing impressive returns on investment (ROI). However, achieving this requires robots that consistently operate at peak efficiency.

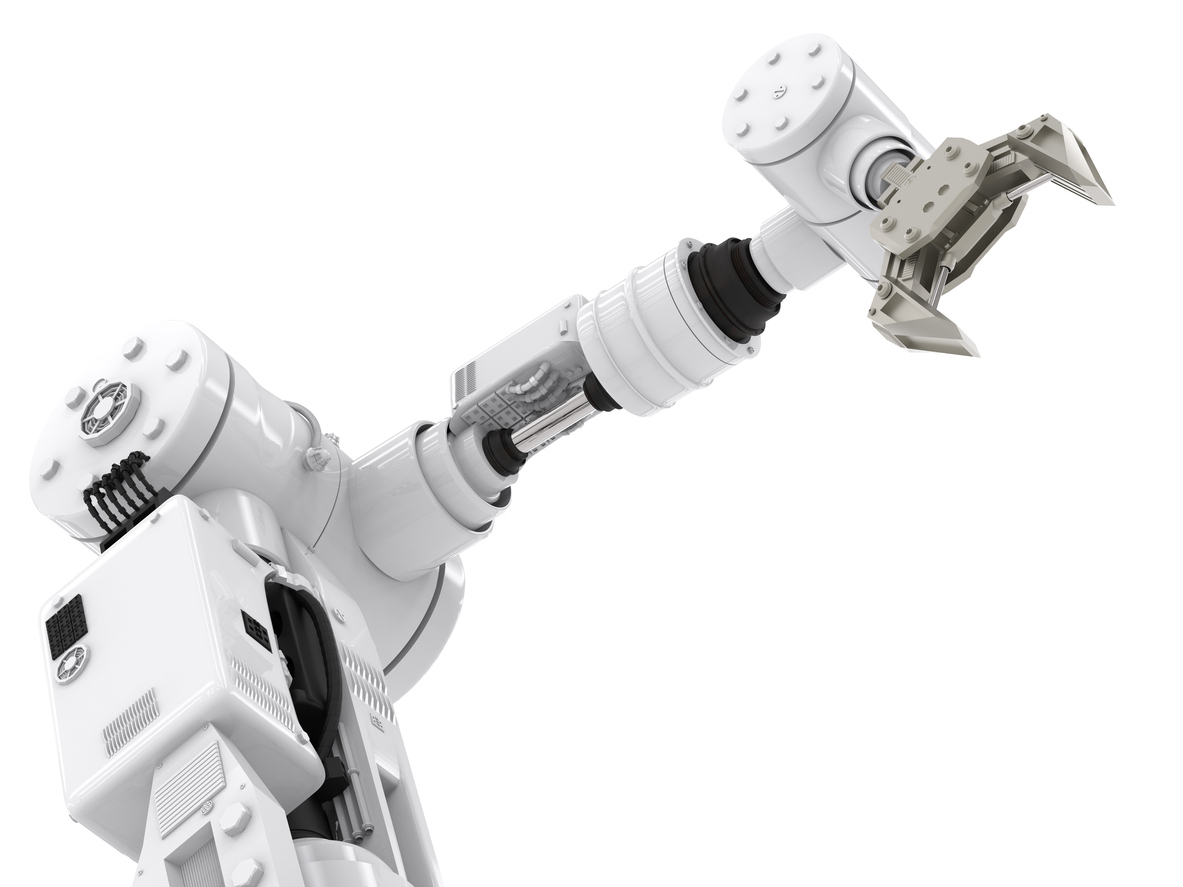

For an industrial robot to be effective in machine tending, it must meet specific performance criteria to ensure long-term ROI. Some crucial features include:

When integrated correctly, machine tending robots can deliver substantial ROI and productivity improvements.

Agriculture equipment manufacturer Genesis Systems Group worked with a client who needed to automate their machine tending processes to boost productivity. They had 16 distinct part types requiring automation with minimal human intervention.

Their solution involved a single robot equipped with dual 3-jaw grippers, 180-degree indexing, a 2D vision system, and red LED lighting. This setup efficiently managed their machines, reducing the overall cycle time to under 60 seconds while maintaining a 95% uptime.

The project proved successful. By automating their processes, the agricultural manufacturer eliminated inefficiencies and achieved excellent ROI.

To explore further insights, check out the Genesis Systems Group's full case study on robotic machine tending.

In conclusion, the integration of industrial robots into machine tending operations offers immense potential for improving productivity and cutting costs. With careful planning and proper execution, manufacturers can unlock the full potential of robotics in their production lines.

For those interested in exploring how robotics can transform their manufacturing processes, consider reaching out to Genesis Systems Group or similar experts in the field. Their expertise can help guide you toward implementing solutions tailored to your specific needs.

As industries continue to evolve, the role of robotics in streamlining operations will only grow stronger. Embracing this technology not only enhances efficiency but also positions businesses to stay competitive in an ever-changing market landscape.

Whether you're in the agricultural sector or any other industry, understanding the capabilities of industrial robots can open up new opportunities for growth and innovation. Stay informed about advancements in robotic technology and how they can benefit your business.

In the coming years, we can expect even more sophisticated robotic solutions that will further reduce cycle times and increase output. Manufacturers who embrace these technologies early stand to gain a significant edge over competitors.

Ultimately, the future of manufacturing is closely tied to the advancement of robotics. By investing in the right robotic solutions today, businesses can prepare themselves for tomorrow's challenges and opportunities.

If you're considering implementing robotic machine tending in your facility, remember to consult with professionals who understand both the technical aspects and the unique requirements of your industry. Their guidance can make all the difference in achieving optimal results.

In summary, industrial robots represent a powerful tool for reducing cycle times and boosting productivity. By focusing on accuracy, adaptability, and payload capacity, manufacturers can maximize the benefits of robotic machine tending. And with real-world success stories like those from Genesis Systems Group, there's every reason to believe that robotics will continue to play a pivotal role in shaping the future of manufacturing.

So, whether you're an agricultural equipment manufacturer or part of another industry, take the time to explore how robotics can enhance your operations. The possibilities are vast, and the rewards can be transformative.

Stay ahead of the curve and let the power of robotics drive your business forward. The path to increased efficiency and profitability starts with understanding the potential of industrial robots in machine tending.

Electric Pellet GrillMinimizing Cycle Times in Machine Tending Using Industrial Robots

Key Characteristics of a Robotic Machine Tending System

Case Study: Agricultural Manufacturer Cuts Cycle Times with Robotics

At Gftop, We Are Committed To Delivering Innovative And Adaptable Outdoor Cooking Appliances That Deliver An Authentic Wood-Fired Cooking Experience. Our Pellet Grills Exemplify This Commitment Perfectly. By Combining The Convenience And Efficiency Of Modern Technology, Our Pellet Grills Enable You To Smoke, Grill, Roast, Or Bake Your Favorite Dishes While Infusing Them With a Distinctive And Genuine Smoky Flavor. Whether You Are a Seasoned Outdoor Cooking Aficionado Or a Novice, The Gftop Pellet Grill Is An Ideal Addition To Your Outdoor Cooking Arsenal, Offering a Genuine Wood-Fired Cooking Experience That Is Both Convenient And Delectable.

pellet grill,outdoor pellet grill,camping pellet grill ,Electric Pellet Grill

gftop , https://www.gftopgrill.com