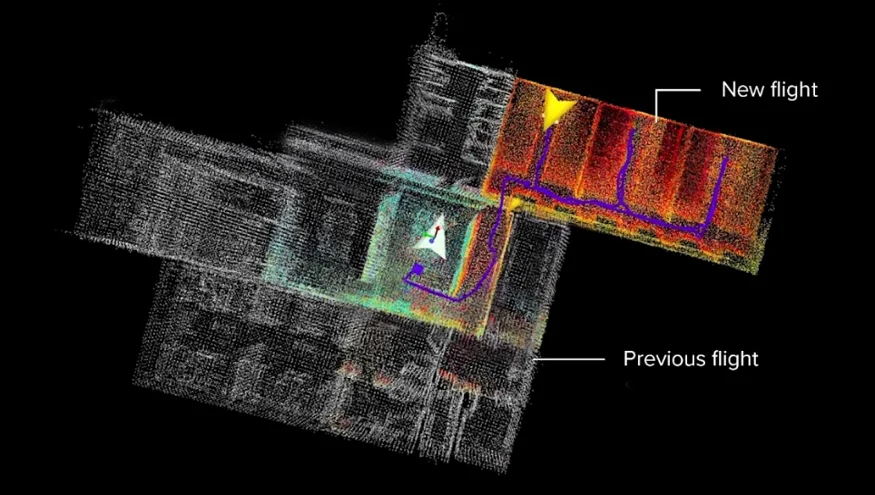

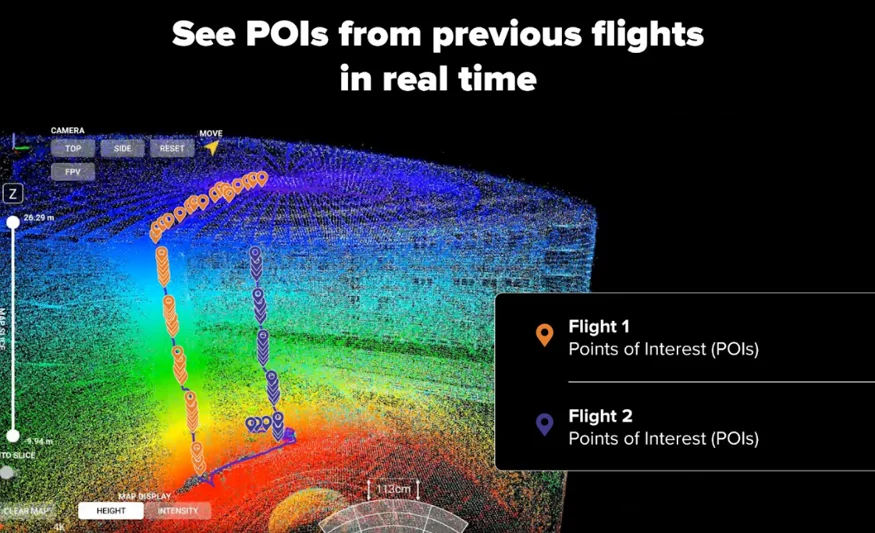

If you're familiar with drone data collection, you'll know that drone operators typically gather data flight by flight, where each flight represents a distinct set of information. However, this approach doesn't align with how asset managers view data. Asset managers are more focused on analyzing the entire asset based on the latest inspection to assess its condition. This is where the new Asset Management software extension for Cockpit and Inspector (the piloting app and processing software for the Elios 3) steps in to bridge the gap between drone data capture and effective asset management. In this article, we'll explore the enhancements brought by the Asset Management software extension and why this will revolutionize the way you handle your data. Asset managers rely on inspection data to monitor how assets age over time and plan preventive maintenance or repairs accordingly. It's crucial for inspectors and inspection firms to provide asset managers with a holistic view of their assets. Currently, this involves organizing data by inspection date and presenting it as a digital twin of the asset. This digital twin ensures the data is easily accessible, navigable, and helps asset managers identify specific areas of interest in relation to the overall asset and broader site operations. However, the benefits of such data organization extend beyond asset managers. Repair teams or personnel tasked with investigating defects find it highly beneficial to examine a digital twin of the asset along with its associated information simultaneously. This streamlines planning for access, ordering parts, and estimating labor and costs. In today’s digital age, digital twins and asset management tools are becoming industry standards. Consequently, the tools used by inspectors must adapt to this way of handling asset data. Traditionally, drones segment data into flights, a practice followed by the Elios 3 until now. With the introduction of the Asset Management extension for Cockpit and Inspector, we're shifting to a method that better aligns with modern asset managers' expectations. The new software extension integrates seamlessly into the entire inspection process, from takeoff to post-processing. The most straightforward and efficient way to ensure data is properly organized is to classify it during data collection. When the Asset Management extension is activated, Elios 3 pilots can create a new asset, begin a fresh inspection within an existing asset, or continue an ongoing inspection prior to each flight. The Asset Management extension allows pilots to visualize layers of data from past flights Beyond simple categorization, data must be spatially structured within a unified frame of reference across flights to enable a clear view of a single digital twin. To achieve this, the Asset Management extension introduces a novel concept to the Elios 3 data capture workflow called relocalization. When conducting additional flights in an asset where you've flown before, you'll begin your inspection with a historical map of the asset derived from all previous inspections. Before starting the flight, the drone performs the relocalization process, aligning its current position within the historical map. As a result, all data captured during the flight is automatically and precisely integrated into the historical map of the asset. With this approach, pilots finish their inspections with the data already sorted by asset, making analysis and management much simpler. There’s nothing more frustrating than returning to the office after an inspection only to discover some data is missing. Besides the benefits outlined above, the Asset Management extension improves the pilot's experience by consistently displaying previously created maps and Points Of Interest across flights during an inspection. This enables pilots to accurately track the completeness of their work and ensure they leave the site with a full dataset. In the future, the Asset Management extension will let users selectively load previous Points Of Interest in addition to the historical map, allowing pilots to revisit areas of concern and repeat inspections multiple times. The Asset Management extension allows pilots to see Points Of Interest from past flights To take advantage of the enhanced features offered by Asset Management, you’ll need an Elios 3 Premium Software Subscription. This subscription is included for 3 years with every Elios 3 Premium and Enterprise drone package and can also be purchased separately for one year at any time. Additionally, a free trial lasting 30 days can be initiated once per Elios 3 that doesn’t already have a Premium Software Subscription. If you're keen to learn more about the Asset Management extension or want to see it in action, visit the Asset Management webpage or get in touch with us. In conclusion, the integration of the Asset Management extension into the Elios 3 workflow represents a significant leap forward in drone-based asset management. By aligning drone data with the expectations of modern asset managers, Flyability is setting a new standard in efficiency and accuracy. Whether you're an inspector, asset manager, or part of a maintenance team, the Asset Management extension offers tools that streamline workflows, improve data integrity, and ultimately save time and resources. Embrace this innovation and elevate your inspection processes today! vsi crusher parts, crusher spare parts, impact crusher parts, spare parts for crushers, vsi crusher spare parts name Zigong Tianyi Industry Co., Ltd , https://www.tyalloypins.comHow Can the Asset Management Extension Transform Your Elios 3 Workflows?

Providing Clarity to Asset Managers

How Does the Asset Management Software Extension Operate?

Other Advantages of Using the Asset Management Extension

How Can You Leverage Asset Management with Flyability?

Key Product Features

Application Scenarios

Customized Solutions

Material Advantages

Designed to withstand the toughest conditions, our VSI crusher parts provide the best durability and efficiency in vertical shaft impact (VSI) crushers, making them ideal for the sand, mining and recycling industries, ensuring optimal performance, reduced downtime and cost-effective operations.

Exceptional Durability: Made from premium materials like high-grade alloys and tungsten carbide, our VSI crusher parts resist wear and extend equipment lifespan.

Precision Engineering: Designed for optimal particle shape and size, enhancing the quality of crushed materials.

Reduced Downtime: High-performance components minimize maintenance needs, keeping your operations running smoothly.

Our VSI crusher parts are widely used in:

Sand Production: Ideal for producing high-quality manufactured sand for construction and industrial use.

Mining Operations: Perfect for crushing hard and abrasive ores, ensuring consistent performance in mineral processing.

Recycling: Efficiently process recycled materials like concrete and asphalt for sustainable construction solutions.

We understand that every crushing operation is unique. That’s why we offer:

Tailored Designs: Custom VSI crusher parts to match specific equipment models and operational requirements.

Expert Support: From material selection to installation guidance, our team ensures seamless integration.

Fast Turnaround: Quick delivery of OEM-quality replacements to minimize downtime.

High-Grade Alloys: Superior strength and wear resistance for extended service life.

Tungsten Carbide: Exceptional hardness and abrasion resistance, ideal for high-impact applications.

Cost-Effective: Durable materials reduce replacement frequency, lowering operational costs.

Choose our VSI Crusher Parts for reliable, high-performance solutions that maximize productivity and minimize downtime. Partner with us to optimize your crushing operations today!