Lixin Outdoor Product Co., Ltd is OEM & ODM manufacturer of inflatable products in the mainland of China with more 17 years of manufacturing experience. products ranges are Inflatable Toys, inflatable pools, inflatable Pool Floats, towable tubes, air furniture and Promotional Items etc. total have more than 1500 employees (4 factories) related to PVC inflatable products. inflatable baby seat, inflatable baby chair, inflatable baby lounger, baby inflatable seat, infant support seat Lixin Outdoor Product Co., Ltd , https://www.pdinflatable.com

Operated under ISO 9001:2015 management system, We had passed factory Audit by Walmart, Taret, Disney ect, also passed all necessary certificates and testing such as ICTI, BSCI, SEMTA,Target FA, NBC Universal, FCCA, SGS, CVS Security, GSV, Disney FAMA ect. We have our own PVC raw materials manufacturing company, all the PVC we produced are compliance with European EN71, American ASTM standard and NON PHTHALATE (6P) standard.

Stepper motors inherently produce vibrations, but understanding their origin is key to minimizing them. These motors control position accurately without encoders by making small rotational steps. However, these steps create minute vibrations, which can amplify into noticeable noise, particularly when connected to other mechanisms. Addressing the source of these vibrations is crucial before attempting any corrective measures.

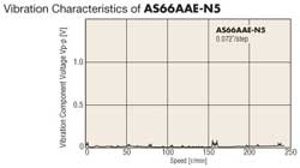

As shown in the video below, the vibration might seem negligible at first glance, but under closer inspection, you'll notice the motor shaft oscillating slightly with each step. This behavior is more pronounced in the following video demonstrating the 1-step vibration characteristics of a 5-phase 0.72° stepper motor and how performance improves at higher speeds.

The air gap between the rotor and stator in a stepper motor allows magnetic flux to flow, while the primary friction comes from the ball bearings. When commanded to move and stop, the lack of sufficient friction in the bearings causes the motor shaft to overshoot and undershoot at each step. This oscillation is known as the "settling time." In some scenarios, this vibration can become significant enough to cause missed steps or excessive noise, particularly when operating at resonant frequencies. Resonant frequency depends on the relationship between torque stiffness and inertia; adjusting either can shift the resonant frequency out of operational ranges, improving performance.

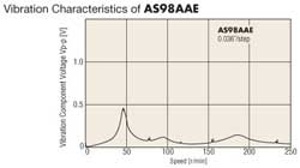

Avoiding resonant frequencies is a straightforward way to mitigate this type of vibration. The next video illustrates how vibration is measured and how it varies at different speeds.

While it may not be possible to eliminate stepper motor vibrations entirely, several approaches exist—both mechanically and electrically—to address the issue. In this post, we’ll explore the most common and effective methods to reduce vibration.

---

### Mechanical Methods to Minimize Vibration

#### 1. Install a Clean Damper

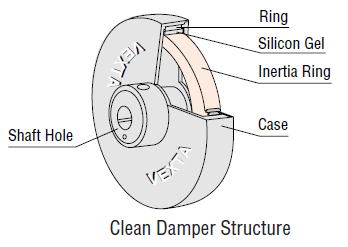

A simple yet effective method to reduce vibration is attaching a clean damper to the motor’s rear shaft. These dampers consist of a hermetically sealed plastic case filled with an inertia body and silicon gel. The added inertia and gel absorb vibrations, providing stable damping effects.

*Figure: Clean damper structure.*

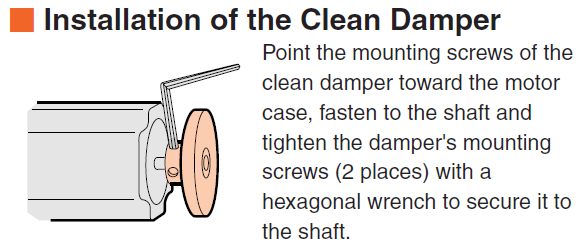

*Figure: Installation of the clean damper.*

#### 2. Use a High-Resolution Stepper Motor

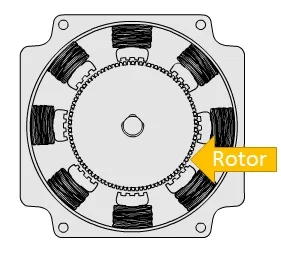

Certain manufacturers offer stepper motors with an increased number of rotor teeth (e.g., 100 instead of 50). Doubling the number of teeth doubles the full-step resolution, reducing vibration amplitude since each step covers a shorter distance. For instance, a standard 1.8° 2-phase stepper motor effectively becomes a 0.9° motor, while a 0.72° 5-phase stepper motor transforms into a 0.36° motor. Finer resolutions can also be achieved through microstepping or gearing.

*Figure: Stepper motor rotor teeth.*

Additionally, high-resolution motors enhance stop position accuracy, offering precise control for demanding applications.

#### 3. Utilize a 5-Phase Stepper Motor

Like high-resolution motors, 5-phase stepper motors also achieve finer full-step resolutions and reduce vibration compared to conventional 2-phase motors. A 5-phase motor retains the same rotor but features 10 stator poles instead of 8, increasing the full-step resolution from 200 to 500 steps per revolution. Stop position accuracy remains dependent on the number of rotor teeth rather than resolution, so high-resolution 2-phase or 5-phase motors still outperform standard models in terms of positional accuracy.

#### 4. Incorporate Geared Stepper Motors

Gearheads are typically used to increase torque while reducing motor speed. However, they also suppress vibration transmission from the motor to the load, reduce overshooting/undershooting through gear friction, and provide stable torque output.

- **Motor Vibration Reduction**: The motor’s own vibration decreases according to the gear ratio.

- **Avoiding Low-Speed Vibration**: Operating at higher speeds avoids the low-speed vibration range.

*Figure: Vibration without a gearhead.*

*Figure: Reduced vibration with gearhead.*

Gearheads play a critical role in stepper motor systems. Learn more about their types and functions [here](#).

#### 5. Thoroughly Size the Motor

Proper motor sizing ensures optimal performance by finding the “sweet spot†where the motor operates efficiently. Avoid sizing a motor at its maximum specifications, as this can lead to stalling. Oversizing should also be avoided, as excessive torque can exacerbate vibration issues. If you’ve oversized a motor, reducing current (which is directly proportional to torque) can alleviate this.

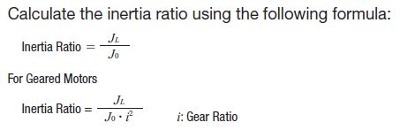

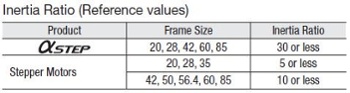

Inertia, the resistance to changes in speed, is often overlooked. When selecting a gear ratio, ensure it doesn’t exceed the recommended “inertia ratio.†For ungeared motors, calculate the inertia ratio by dividing total load inertia by rotor inertia. For geared motors, divide total load inertia by rotor inertia multiplied by the square of the gear ratio.

*Figure: Inertia ratio formula.*

*Figure: Permissible inertia ratios by product.*

Thorough analysis and appropriate safety margins are essential for long-term performance. Many manufacturers provide sizing tools to simplify this process.

---

### Electrical Methods to Minimize Vibration

#### 1. Use a Microstepping Driver

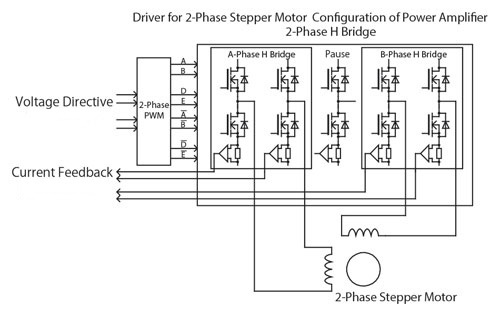

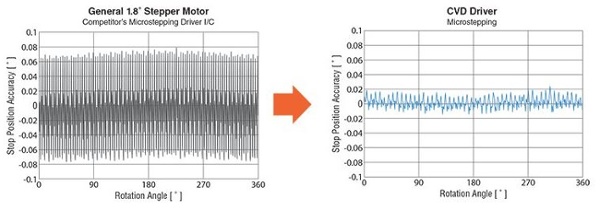

Microstepping is widely recommended for reducing vibration. This technique divides motor current between phases via a driver, allowing precise torque and position control. A driver’s ability to regulate current uniformly significantly impacts its effectiveness in reducing torque ripple, vibration, and audible noise. Poor current regulation due to inconsistent phase currents leads to uneven steps and torque, causing vibration regardless of the motor quality.

The following video demonstrates microstepping in action.

However, microstepping alone often fails to address vibration across all speed ranges.

#### 2. Employ a Driver That Resolves Vibrations Independently

Oriental Motor’s CVD bipolar constant current chopper drivers (from the CVK Series) are designed specifically to minimize vibration across all speed ranges by addressing each vibration type individually. With individual phase current detectors, these drivers regulate current exceptionally well and provide uniform current waveforms.

*Figure: Individual phase current feedback detection of CVD drivers.*

Compared to traditional analog potentiometers, CVD drivers utilize digitized current control, improving motor stop accuracy. While stop position accuracy is specified at ±0.05°, real-world performance exceeds expectations, even during microstepping.

*Figure: Vibration comparison between drivers.*

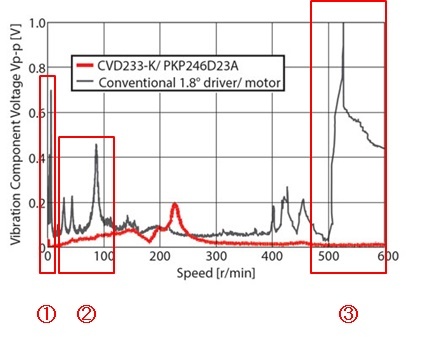

CVD drivers categorize three main types of vibrations:

1. **Low-Speed Vibration** (0–50 RPM): Caused by step movements.

2. **Mid-Speed Vibration** (50–200 RPM): Resulting from torque variance or resonant frequency.

3. **High-Speed Vibration** (500 RPM+): Triggered by back EMF and instability in constant current control.

*Figure: CVD driver vibration comparison.*

The CVD driver’s **Smooth Drive** function provides microstepping performance with full-step resolution control, reducing vibration, especially in the 0–50 RPM range. Additionally, its **current excitation phase correction** optimizes torque vectors between 50–200 RPM, minimizing torque ripple and resonance. Lastly, a **current compensation control** reduces high-speed vibration (500 RPM+) using motor data and proprietary algorithms.

For more details about the **CVK Series CVD driver’s vibration suppression technologies**, watch the video below and refer to the white paper.

---

By combining mechanical and electrical strategies, stepper motor vibration can be effectively managed. Proper sizing, high-resolution motors, geared solutions, and advanced drivers like the CVD series are all valuable tools in achieving smooth, reliable performance.