PD Toys plastic Co., Ltd is OEM & ODM manufacturer of inflatable products in the mainland of China with more 17 years of manufacturing experience. products ranges are Inflatable Toys, inflatable pools, inflatable Pool Floats, towable tubes, air furniture and Promotional Items etc. total have more than 1500 employees (4 factories) related to PVC inflatable products.

Operated under ISO 9001:2015 management system, We had passed factory Audit by Walmart, Taret, Disney ect, also passed all necessary certificates and testing such as ICTI, BSCI, SEMTA,Target FA, NBC Universal, FCCA, SGS, CVS Security, GSV, Disney FAMA ect. We have our own PVC raw materials manufacturing company, all the PVC we produced are compliance with European EN71, American ASTM standard and NON PHTHALATE (6P) standard.

camping mattress, self inflating mattress, double camping mattress, inflatable sleeping pad, double sleeping mat Lixin Outdoor Product Co., Ltd , https://www.pdinflatable.com #### 4. Use geared stepper motors.

A gearhead is commonly used to increase torque while reducing motor speed. Its increased rigidity helps suppress the transmission of vibration from the motor to the load, and its consistent torque output ensures more stable operation. Additionally, gear friction can help reduce overshooting and undershooting.

Key benefits include:

- Reduced motor vibration in proportion to the gear ratio.

- Avoidance of the low-speed vibration range since the motor operates at higher speeds.

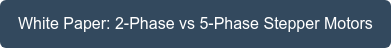

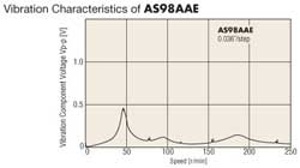

Compare the difference with and without a gearhead:

| Without Gearhead | With Gearhead |

|------------------|---------------|

|  |  |

Learn more about gearheads and their applications:

#### 4. Use geared stepper motors.

A gearhead is commonly used to increase torque while reducing motor speed. Its increased rigidity helps suppress the transmission of vibration from the motor to the load, and its consistent torque output ensures more stable operation. Additionally, gear friction can help reduce overshooting and undershooting.

Key benefits include:

- Reduced motor vibration in proportion to the gear ratio.

- Avoidance of the low-speed vibration range since the motor operates at higher speeds.

Compare the difference with and without a gearhead:

| Without Gearhead | With Gearhead |

|------------------|---------------|

|  |  |

Learn more about gearheads and their applications:

#### 5. Properly size the motor.

Sizing a motor involves finding the optimal balance where it operates efficiently. Over-sizing a stepper motor can lead to excessive torque, which may increase vibration. To prevent this, reduce the motor current (as current is directly proportional to torque).

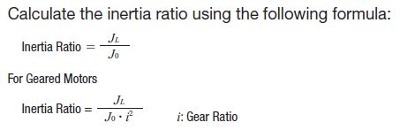

Inertia, the resistance to changes in speed, is often overlooked. When selecting a gear ratio, ensure it doesn’t exceed the recommended "inertia ratio." For ungeared motors, calculate the inertia ratio by dividing the total load inertia by the rotor inertia. For geared motors, divide the total load inertia by the rotor inertia multiplied by the gear ratio squared.

Refer to the formulas below for reference:

#### 5. Properly size the motor.

Sizing a motor involves finding the optimal balance where it operates efficiently. Over-sizing a stepper motor can lead to excessive torque, which may increase vibration. To prevent this, reduce the motor current (as current is directly proportional to torque).

Inertia, the resistance to changes in speed, is often overlooked. When selecting a gear ratio, ensure it doesn’t exceed the recommended "inertia ratio." For ungeared motors, calculate the inertia ratio by dividing the total load inertia by the rotor inertia. For geared motors, divide the total load inertia by the rotor inertia multiplied by the gear ratio squared.

Refer to the formulas below for reference:

Proper motor sizing, along with adequate safety factors, guarantees long-term performance. Many manufacturers offer sizing tools to simplify this process.

---

### Electrical Methods to Minimize Vibration

#### 1. Use a microstepping stepper motor driver.

Microstepping is widely considered the most effective method. It divides the motor current between phases using a driver, which allows for precise torque and position control. Inconsistent phase currents increase vibration due to uneven steps or torque. If the driver cannot regulate current effectively or provide a uniform current waveform, the motor will vibrate regardless of its quality.

Watch the video below to understand how microstepping works:

However, microstepping alone may not solve vibration issues across all speed ranges.

#### 2. Use a driver that resolves vibrations independently.

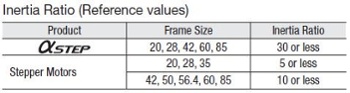

Oriental Motor’s CVD bipolar constant current chopper drivers (from the CVK series) are specifically designed to provide low-vibration performance across all speed ranges by addressing each type of vibration individually. Individual phase current detectors enable these drivers to regulate current effectively and provide a uniform current waveform.

Compared to traditional analog potentiometers, the CVD drivers employ digitized current control, offering better motor stop accuracy. Although we specify a stop position accuracy of ±0.05°, the motor performs significantly better in real-world conditions, even during microstepping.

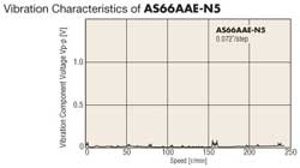

See the difference in vibration reduction:

Proper motor sizing, along with adequate safety factors, guarantees long-term performance. Many manufacturers offer sizing tools to simplify this process.

---

### Electrical Methods to Minimize Vibration

#### 1. Use a microstepping stepper motor driver.

Microstepping is widely considered the most effective method. It divides the motor current between phases using a driver, which allows for precise torque and position control. Inconsistent phase currents increase vibration due to uneven steps or torque. If the driver cannot regulate current effectively or provide a uniform current waveform, the motor will vibrate regardless of its quality.

Watch the video below to understand how microstepping works:

However, microstepping alone may not solve vibration issues across all speed ranges.

#### 2. Use a driver that resolves vibrations independently.

Oriental Motor’s CVD bipolar constant current chopper drivers (from the CVK series) are specifically designed to provide low-vibration performance across all speed ranges by addressing each type of vibration individually. Individual phase current detectors enable these drivers to regulate current effectively and provide a uniform current waveform.

Compared to traditional analog potentiometers, the CVD drivers employ digitized current control, offering better motor stop accuracy. Although we specify a stop position accuracy of ±0.05°, the motor performs significantly better in real-world conditions, even during microstepping.

See the difference in vibration reduction:

The CVD drivers categorize vibrations into three main types:

1. **Low-speed vibration** (0–50 RPM) caused by step movement.

2. **Mid-speed vibration** (50–200 RPM) caused by torque variance or resonant frequency.

3. **High-speed vibration** (above 500 RPM) caused by back EMF and instability in constant current control.

The CVD drivers feature a unique **Smooth Drive** full-time microstepping function, which combines microstepping performance with full-step resolution control. When activated, the driver internally microsteps the motor (2,048 steps per 1.8° full step) while the controller sends pulses at full-step resolution. Originally developed to reduce the burden on the pulse generator, this function significantly reduces vibration, especially in the low-speed range (0–50 RPM).

Additionally, the driver includes a **current excitation phase correction** function that optimizes torque vectors, reducing vibration in the 50–200 RPM range. This minimizes torque ripple and resonance. Furthermore, a **current compensation control** reduces high-speed vibration (above 500 RPM) using motor data and a proprietary algorithm—only possible with a manufacturer that designs both the motor and the driver.

For more details about the **CVK Series CVD driver’s vibration suppression technologies**, check out the video below and the accompanying white paper.

---

Even with the best mechanical and electrical solutions, external components in the system may still contribute to vibration. Ensure all connections are secure and consider using rubber grommets to dampen noise if necessary.

By combining these methods, you can significantly reduce stepper motor vibrations and enhance overall system performance.

The CVD drivers categorize vibrations into three main types:

1. **Low-speed vibration** (0–50 RPM) caused by step movement.

2. **Mid-speed vibration** (50–200 RPM) caused by torque variance or resonant frequency.

3. **High-speed vibration** (above 500 RPM) caused by back EMF and instability in constant current control.

The CVD drivers feature a unique **Smooth Drive** full-time microstepping function, which combines microstepping performance with full-step resolution control. When activated, the driver internally microsteps the motor (2,048 steps per 1.8° full step) while the controller sends pulses at full-step resolution. Originally developed to reduce the burden on the pulse generator, this function significantly reduces vibration, especially in the low-speed range (0–50 RPM).

Additionally, the driver includes a **current excitation phase correction** function that optimizes torque vectors, reducing vibration in the 50–200 RPM range. This minimizes torque ripple and resonance. Furthermore, a **current compensation control** reduces high-speed vibration (above 500 RPM) using motor data and a proprietary algorithm—only possible with a manufacturer that designs both the motor and the driver.

For more details about the **CVK Series CVD driver’s vibration suppression technologies**, check out the video below and the accompanying white paper.

---

Even with the best mechanical and electrical solutions, external components in the system may still contribute to vibration. Ensure all connections are secure and consider using rubber grommets to dampen noise if necessary.

By combining these methods, you can significantly reduce stepper motor vibrations and enhance overall system performance.

Stepper motors are known for their precision and reliability in position control, but they do have a tendency to vibrate. Understanding the source of these vibrations is the first step in minimizing them. A stepper motor moves in small increments, or "steps," which are usually set at specific angles. However, between these steps, the motor experiences minute vibrations. These vibrations are usually imperceptible under normal circumstances but can sometimes amplify into noticeable noise, especially when connected to other machinery. It’s crucial to address the root cause of the vibrations before attempting to resolve them.

Take a look at the video below, which illustrates the subtle nature of stepper motor vibrations. While the movement might appear smooth to the naked eye, a closer inspection reveals that the motor shaft oscillates slightly with each step. In this demonstration, we use a five-phase stepper motor with a step angle of 0.72 degrees to showcase its step-by-step vibration characteristics and why smoother performance is typically observed at higher speeds.

The interaction between the rotor and stator within a stepper motor creates a tiny air gap where magnetic flux flows. The only significant friction comes from the ball bearings. When the motor is commanded to move and stop, the lack of sufficient friction in the ball bearings causes the rotor to overshoot and undershoot at every step due to inertia. The time it takes for the rotor to stabilize after this overshooting and undershooting is referred to as the "settling time."

In certain situations, these vibrations can become severe enough to result in missed steps or excessive noise, particularly when operating at the motor's resonant frequency. Resonant frequency depends on the relationship between torque stiffness and inertia. Adjusting either of these parameters can shift the resonant frequency out of the operational range, improving overall performance. One simple way to avoid this kind of vibration is by steering clear of the resonant frequency.

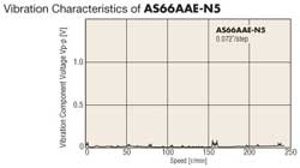

Let’s take a look at another video that shows how vibration is measured and how it changes at different speeds.

Although it may not be possible to eliminate stepper motor vibrations entirely, there are several ways to address this issue, both mechanically and electrically. In this article, we’ll explore the most common and effective methods for reducing vibration.

---

### Mechanical Methods to Minimize Vibration

#### 1. Install a clean damper.

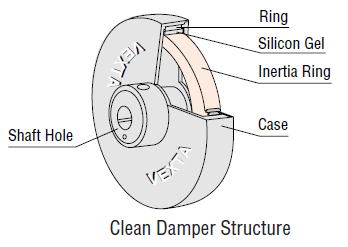

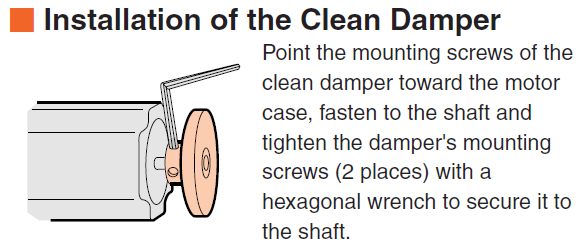

One straightforward method to reduce vibration is attaching a clean damper to the rear shaft of the motor. A clean damper consists of a hermetically sealed plastic case filled with an inertia body packed with silicone gel. The added inertia and gel help absorb vibrations, providing a stable damping effect.

Here’s an illustration of the damper's structure and installation:

#### 2. Use a high-resolution stepper motor.

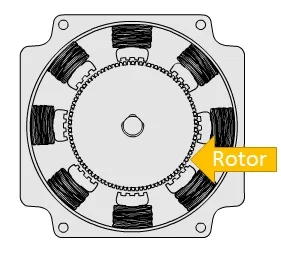

Some manufacturers produce stepper motors with a higher number of rotor teeth (100 instead of 50). Increasing the number of teeth doubles the full-step resolution and reduces vibration amplitude because the motor moves a shorter distance with each step. For instance, a standard 1.8-degree two-phase stepper motor becomes a 0.9-degree motor, and a 0.72-degree five-phase stepper motor becomes a 0.36-degree motor. Higher resolutions can also be achieved through microstepping or gearing.

Additionally, the 100-tooth rotor improves the motor’s stop position accuracy, making it ideal for precise positioning applications.

Watch the video below to see the stop position accuracy in action:

#### 3. Use a five-phase stepper motor.

Like a high-resolution stepper motor, a five-phase stepper motor with a 0.72-degree step angle achieves finer full-step resolution and reduces vibration compared to a two-phase stepper motor with a 1.8-degree step angle. A five-phase motor has the same rotor but ten stator poles instead of eight, increasing the full-step resolution from 200 to 500 steps per revolution. Stop position accuracy depends on the number of rotor teeth, so high-resolution two-phase or five-phase motors still offer better stop accuracy than standard models.

Learn more about five-phase stepper motors in the white paper below: